This project is a redesign of the bottle used for the toilet cleaning product “Klorin”. The brief was to develop a new bottle that best fulfilled the production demands of plastic blow molding, while meeting certain requirements for user handling.

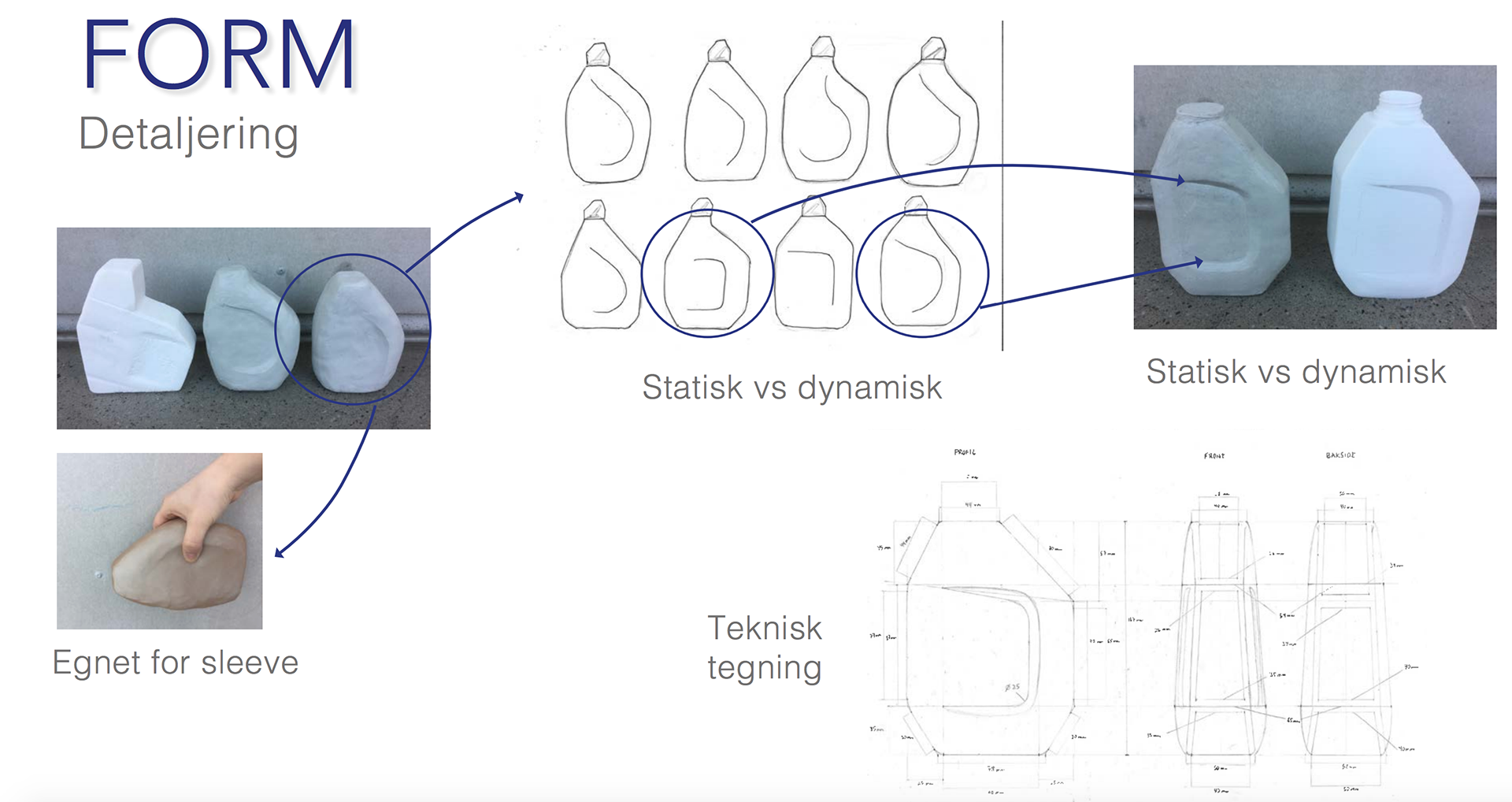

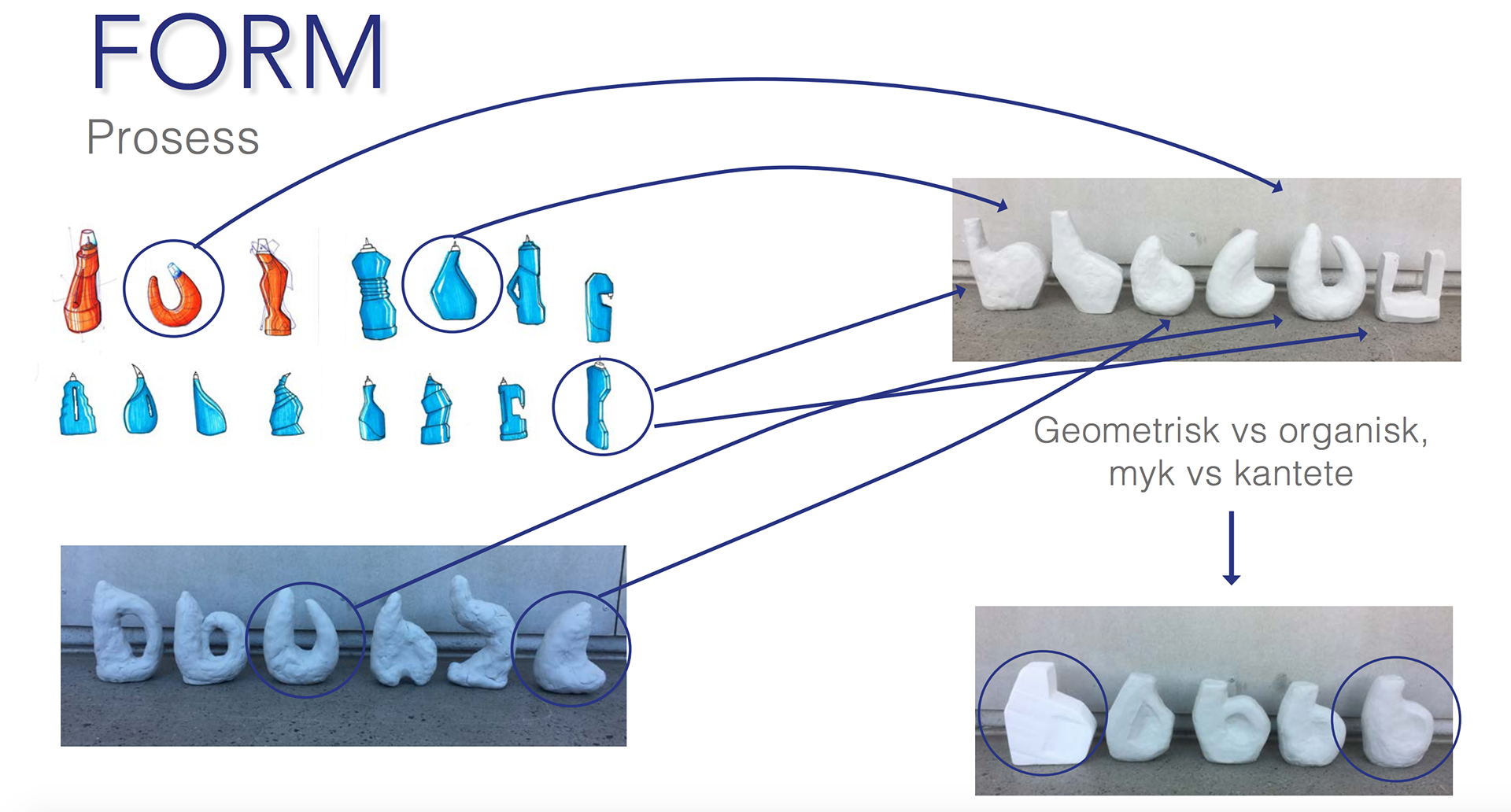

The framework of the project was given by the company Orkla. They presented several problems with the existing packaging, such as the fact that the bottlenecks are tilted, even though the bottles are filled vertically during production. Based on our research we also chose to improve the usability of the bottle. Our solution is a bottle that is shorter, has a more stable grip and an opening that allows for vertical filling. Not only is it optimized for production, it is also easier to use and store at home than the original bottle.

Fourth semester at AHO (GK4).

Length of Project: 3 weeks.

Designers: Hanna Nordland, Marte Rennemo & Hans Kristian Villa

Awards /Presentations/Exhibitions:

2018 - AHO WORKS (2017-2018) Representative (GK4)

User Sequence

Problem Areas

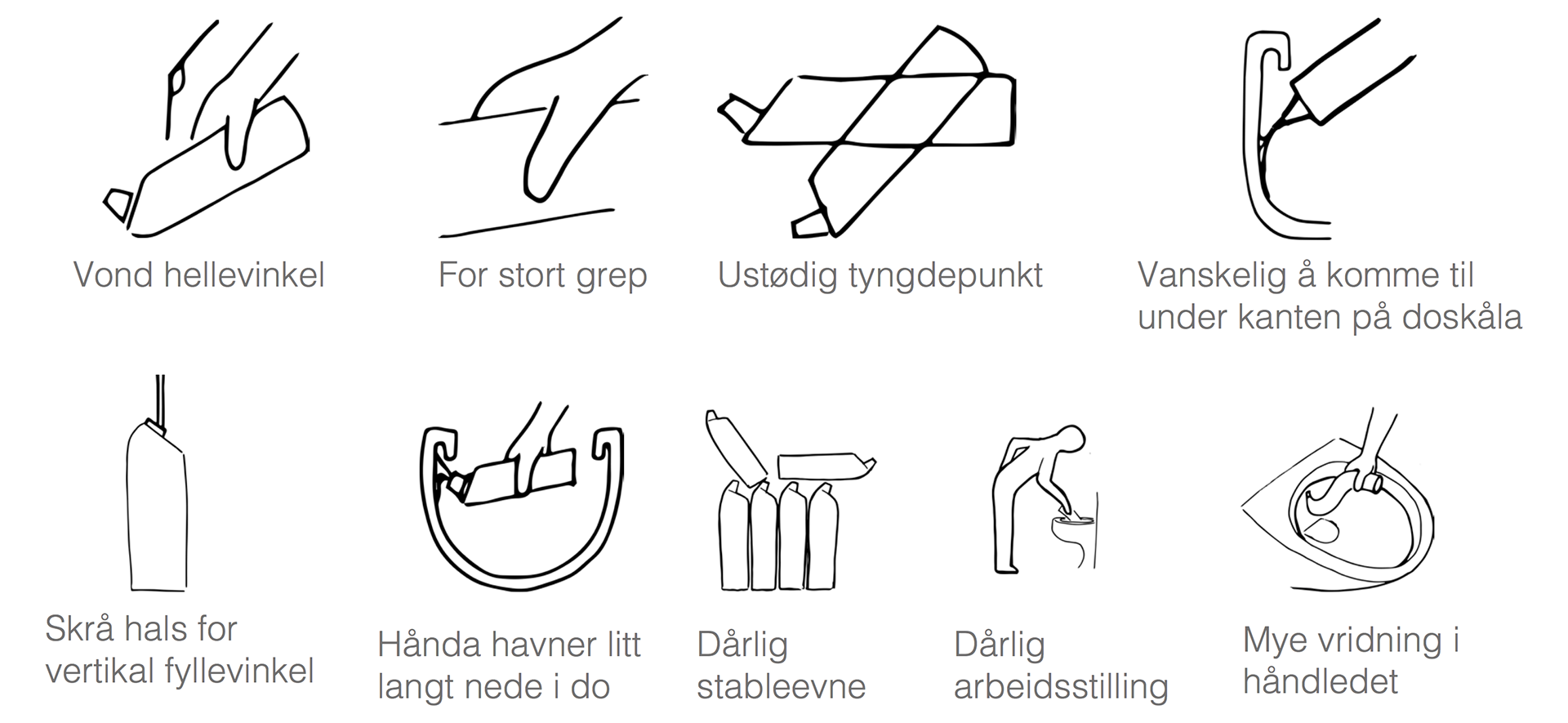

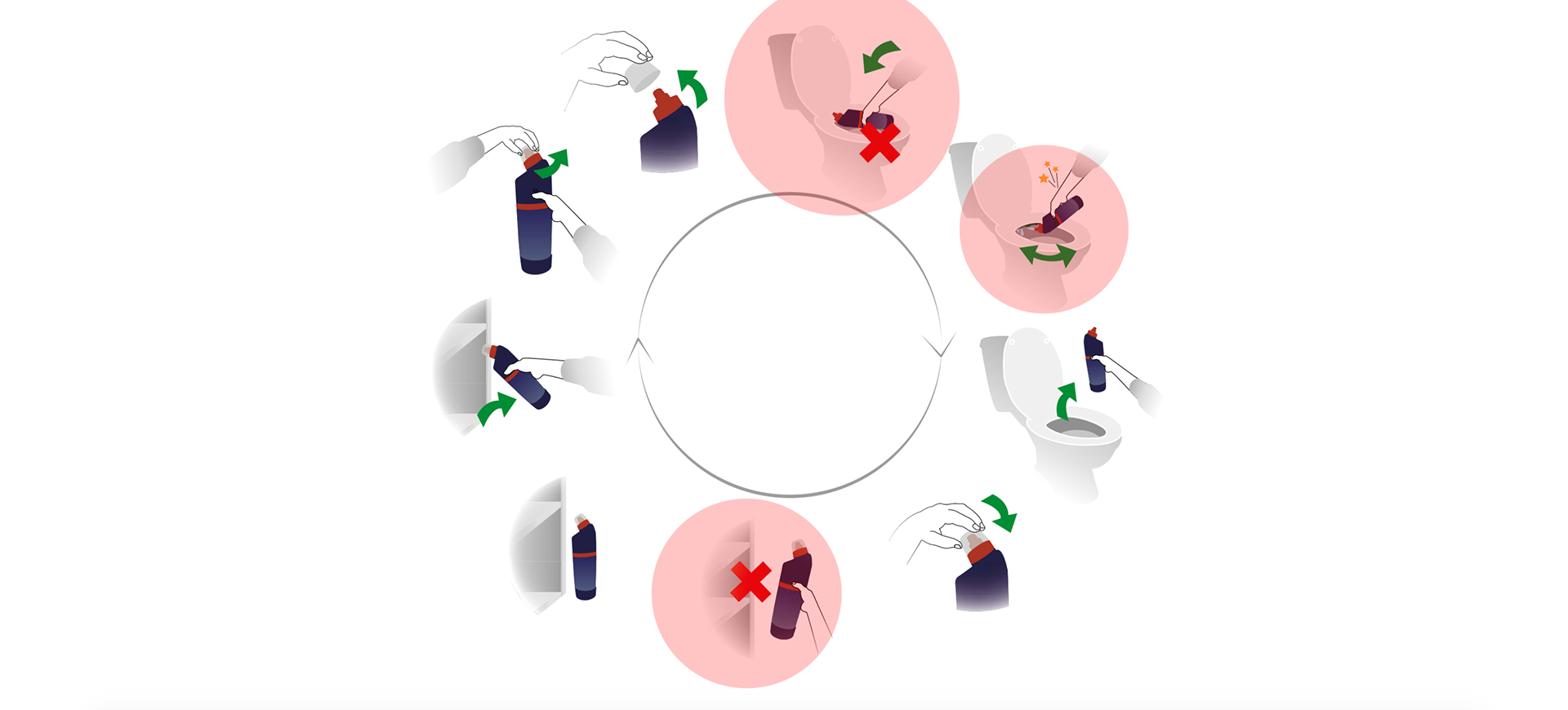

Defining the Problem Areas.

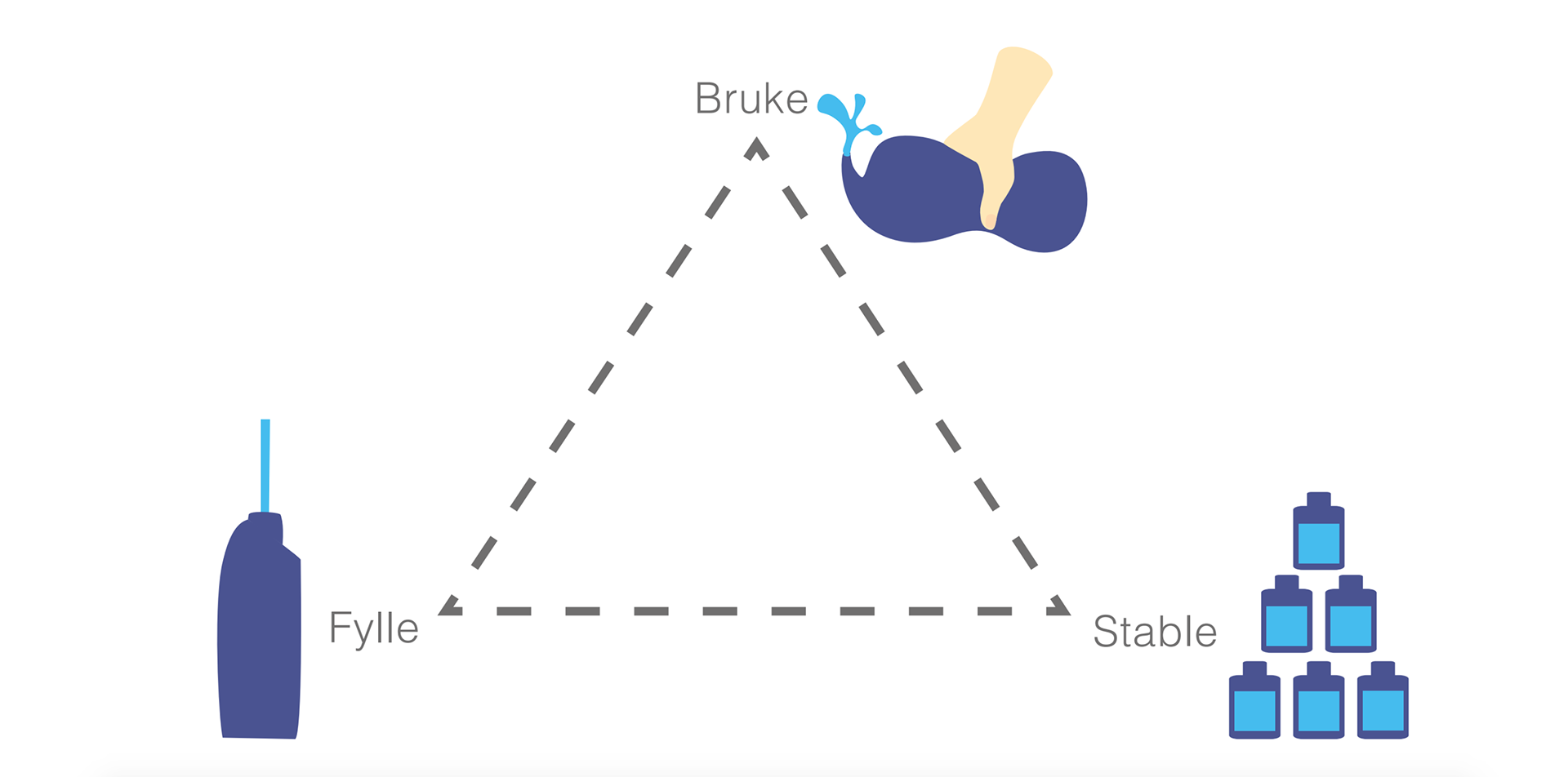

Filling - Use - Stacking

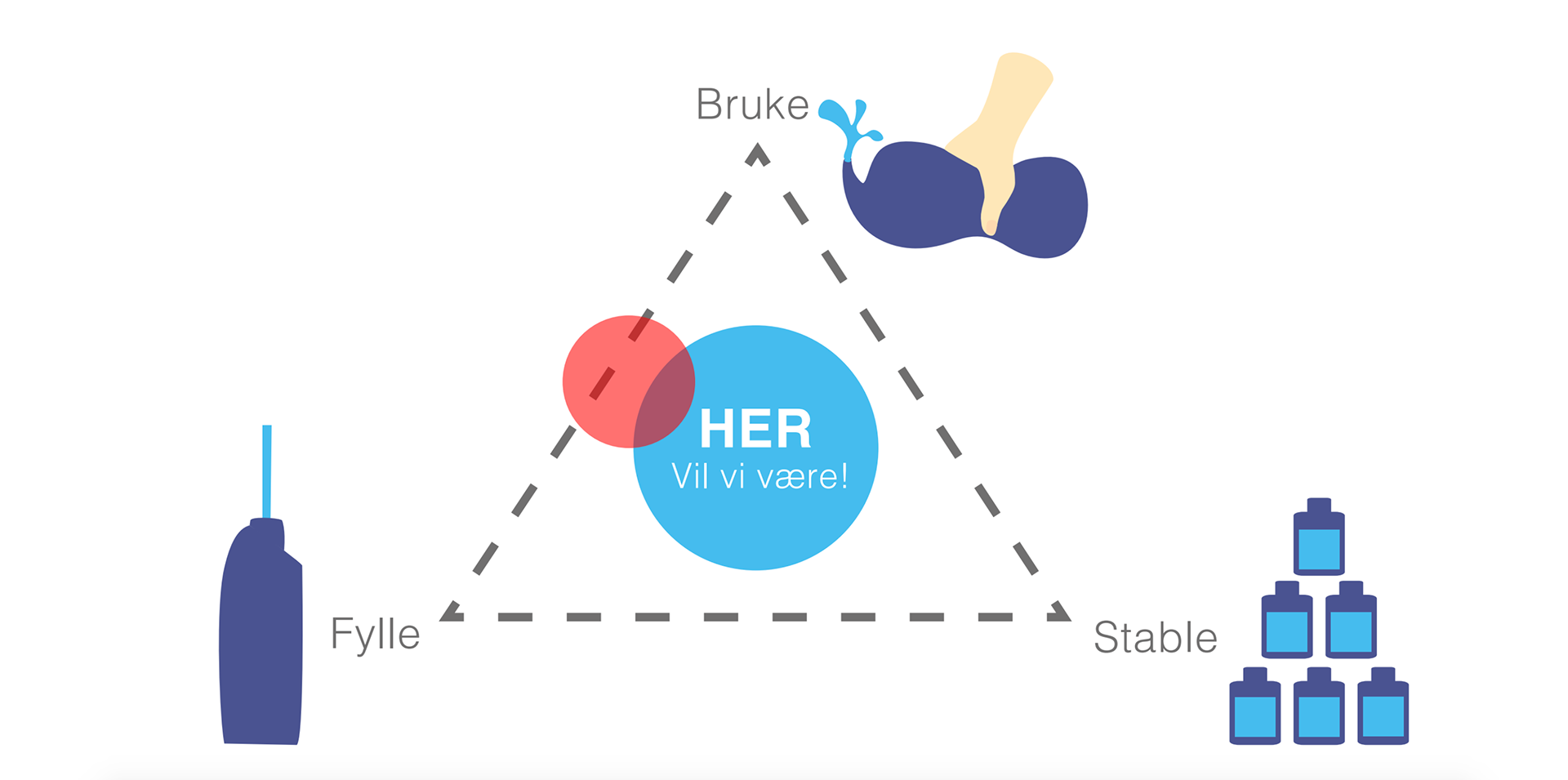

This is where we want to be

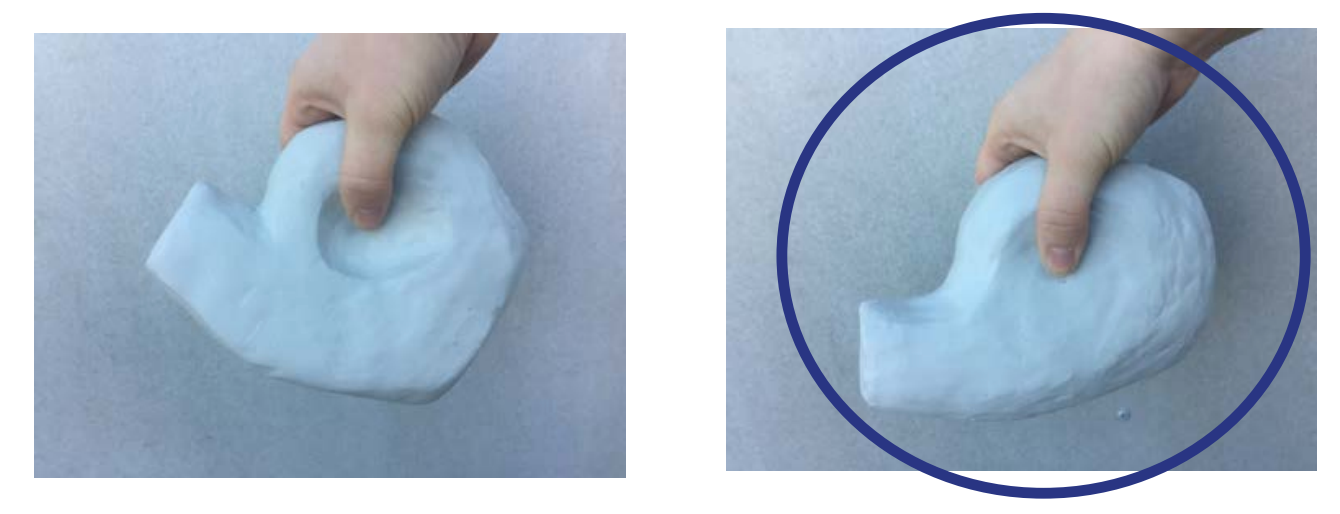

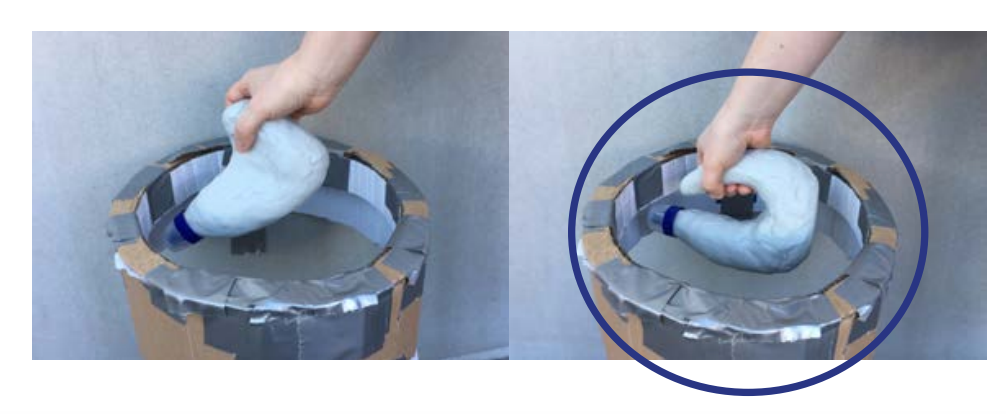

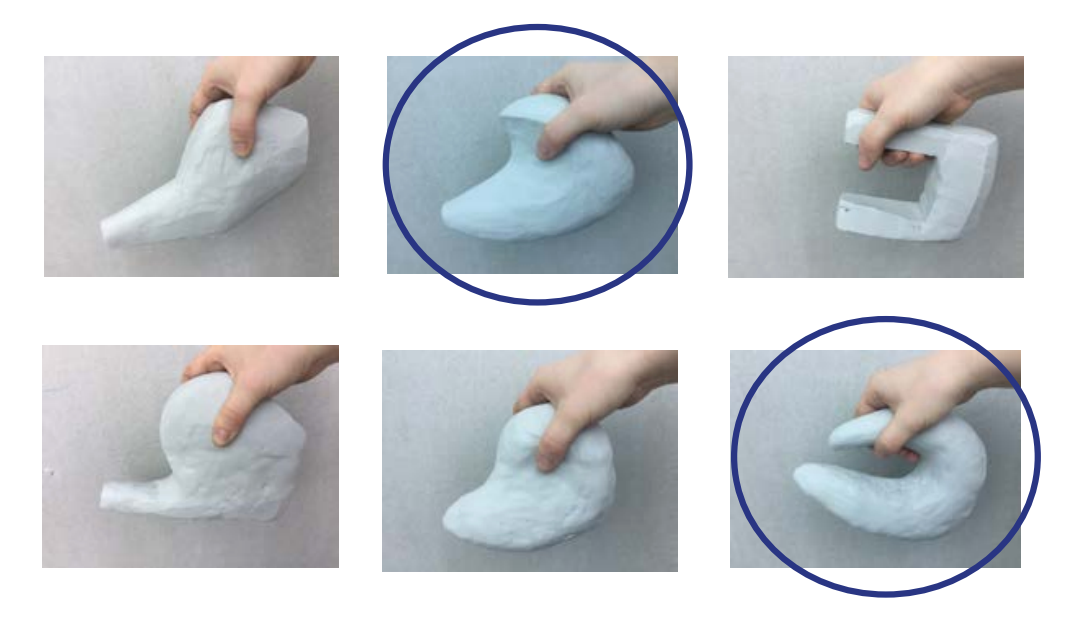

Focusing on function-driven form and iterating on usability.

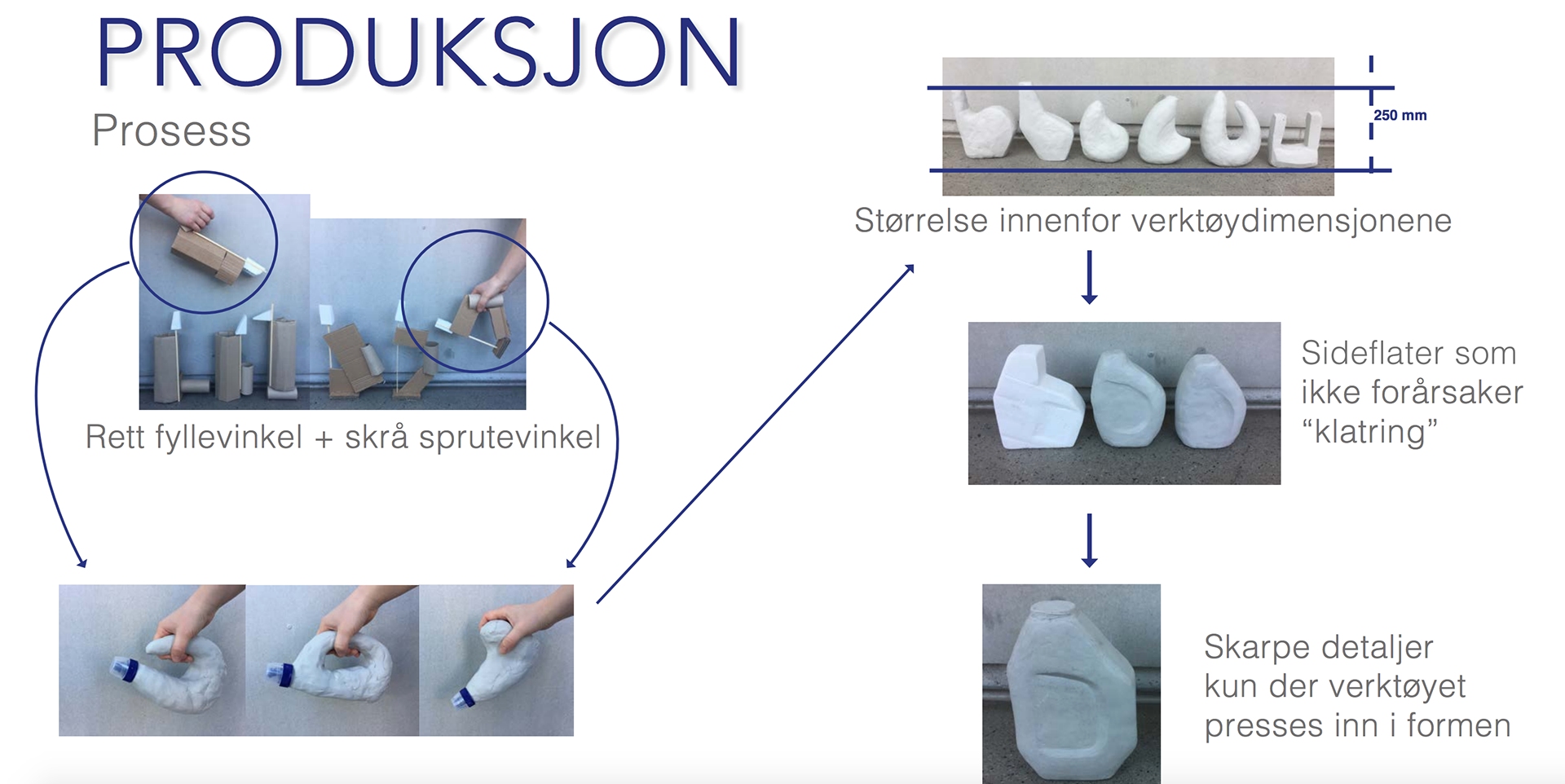

Keeping Production in Mind

Iterations on 3D printing

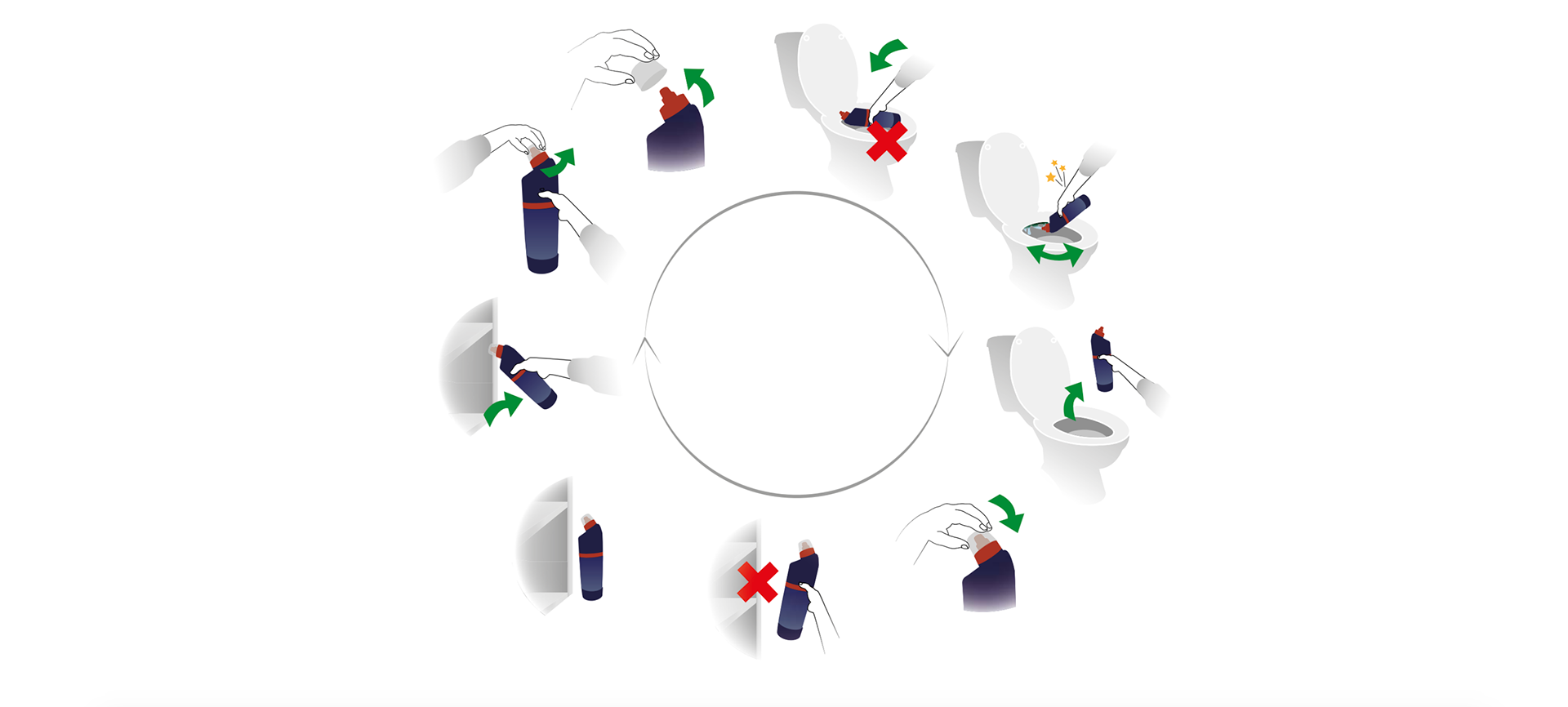

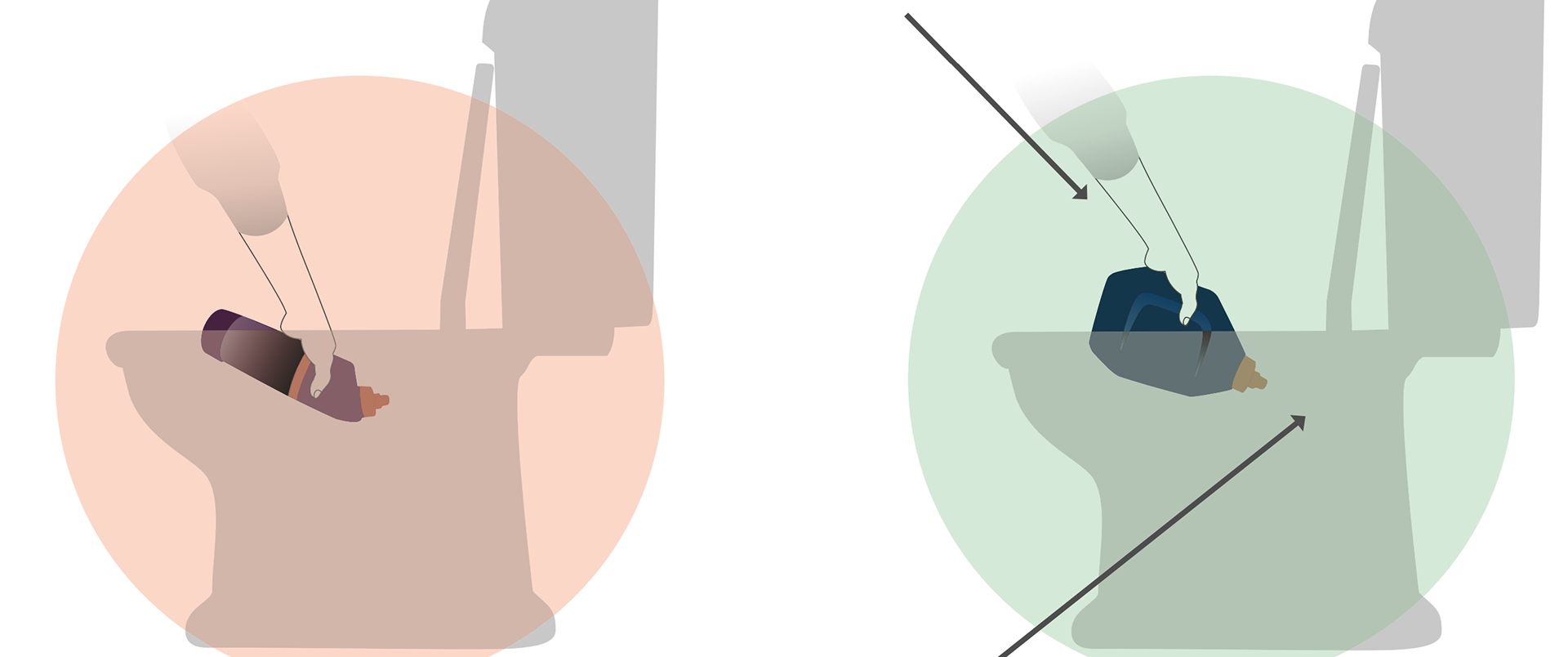

Sequence of Use - Old bottle

Problem Areas

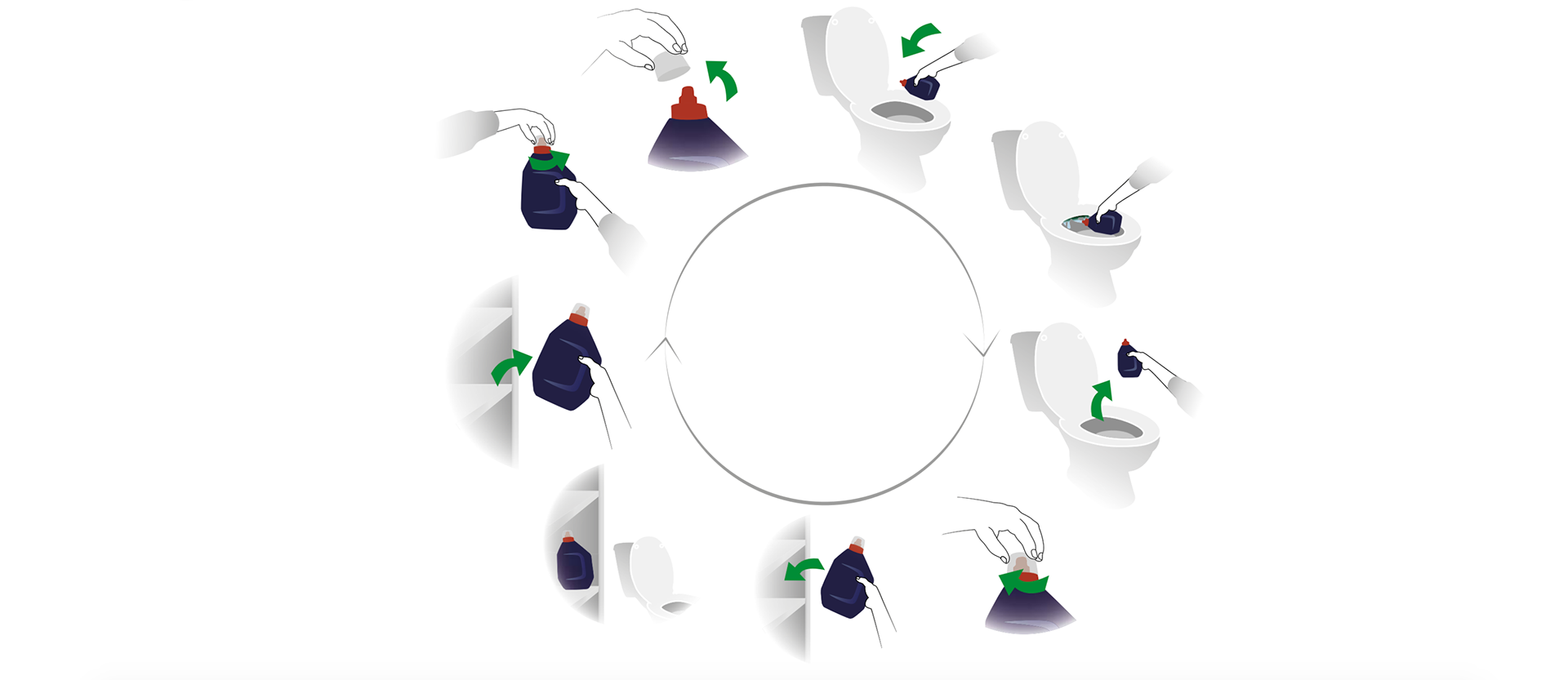

Sequence of Use - Our Solution

Old bottle vs Our Solution

Molding Form

Blow Molding Machine

Blow Molded Bottles